comparison of our vawt performance

VAWT CONCEPTS

Vertical Axis Wind Turbines (VAWTs) find widespread use in urban areas for various applications, such as lighting, home power generation, large outdoor billboards, telecommunication stations, oil fields, wind energy buildings, and highway monitoring systems. These turbines are highly regarded for their energy conversion efficiency, noise-free operation, safety, reliability, and low maintenance requirements.

VAWTs come in different shapes and sizes, shaped by design concepts and manufacturing capabilities. In comparison to traditional Horizontal Axis Wind Turbines (HAWTs), VAWTs offer distinct advantages that make them more efficient in power generation. Currently, there are two types of VAWTs in the wind turbine market.

The first type is the Drag-type VAWT, also known as Savonius or S-shape VAWT. Savonius VAWT has the advantage of generating a larger starting torque, but it suffers from vibrations and low power efficiency during rotation due to asymmetric airflow creating a sideways push. The wind utilization rate for Savonius VAWT is relatively low, around 2/27, making it less efficient in energy conversion.

The second type is the Lift-type VAWT, which relies on the lift of the airflow to rotate its blades. The blades are designed based on aerofoil theory, and the driving torque is generated by the resultant force when the air flows across the blades. Two typical Lift-type VAWTs are the Darrieus and H-shape turbines. Darrieus turbines have two or three blades and boast a simpler design structure without the need for a supporting tower, resulting in lower costs. However, they require external force to initiate rotation and must shut down in gusty winds for safety reasons.

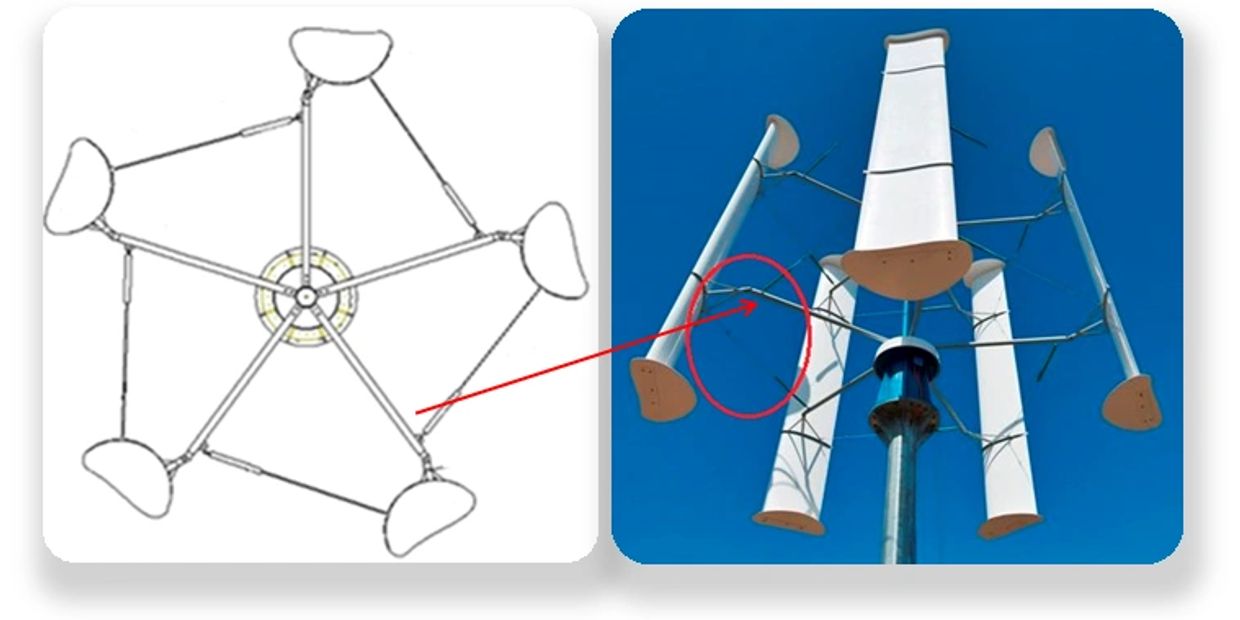

Within the H-shape VAWTs, the straight-shape blade design model proves to be the most efficient. To achieve self-start capability, a minimum of 4 blades is recommended, as 3 or fewer blades lead to numerous "dead-points" where an external force is needed to initiate rotation. A 5-blade model, on the other hand, is nearly "dead-points" free. Straight-shape blade VAWTs excel in maintaining maximum air pressure inside the windmill, resulting in superior aerodynamic performance compared to other H-shape VAWTs.

TALOS new designs for H-shape VAWT are monumental innovations in the wind turbine industry. TALOS unique technologies are patented in many countries including the United States.

TALOS KEY PATENTED DESIGNS:

1) Blade Shape Perfection

2) Golden Ratio (blade width over length)

3) Auto-adjusting blade angle for the most efficient power generation

4) Overspeed Regulation Structure

- Auto-adjustable blade angle to reduce speed

- Overspeed auto-brake control

THE Super Turbine

On a flat wind farm, this Super Turbine built with hundreds of blades, uses "active real-time attack angle regulation" technology. The angle of blades can be adjusted automatically on a small group basis, according to their position, wind direction, and wind speed.

Blade groups drive hundreds of high-speed mini-generators to produce power. A single turbo super turbine could generate up to 50 MW, while a mini super turbine could generate up to 7 MW.